| Article No. | DN | ø D (mm) | PN (bar) | L (mm) | weight (kg) | NPK No. 411 | NPK No. 412 | BIM / CAD | Availability | watchlist |

|---|---|---|---|---|---|---|---|---|---|---|

| 7100065082 | 65 | 82 | 16 | 60 | 3.400 | 278217 | 278219 | ex warehouse | ||

| 7100080098 | 80 | 98 | 16 | 65 | 2.800 | 278218 | 273221 | ex warehouse | ||

| 7100100118 | 100 | 118 | 16 | 60 | 2.900 | 278219 | 273222 | ex warehouse | ||

| 7100125144 | 125 | 144 | 16 | 65 | 4.300 | 278221 | 273223 | ex warehouse | ||

| 7100150170 | 150 | 170 | 16 | 65 | 5.100 | 278222 | 273224 | ex warehouse | ||

| 7100200222 | 200 | 222 | 10 | 70 | 7.300 | 278223 | 273235 | ex warehouse | ||

| 7100251274 | 250 | 274 | 16 | 80 | 10.900 | 278224 | 273246 | ex warehouse | ||

| 7100300326 | 300 | 326 | 10 | 80 | 13.800 | 278225 | 273237 | ex warehouse | ||

| 7100301326 | 300 | 326 | 16 | 80 | 13.800 | 278225 | 273247 | ex warehouse | ||

| 7100400429 | 400 | 429 | 10 | 105 | 22.500 | 278227 | 273238 | on demand |

DN

watchlist

| 7100065082 | 65 | |

| ø D | 82 mm | |

| PN | 16 bar | |

| L | 60 mm | |

| weight | 3.400 kg | |

| NPK No. 411 | 278217 | |

| NPK No. 412 | 278219 | |

| BIM-Data | https://www.cadenas.de/de/7100065082 | |

| Availability | ex warehouse | |

| 7100080098 | 80 | |

| ø D | 98 mm | |

| PN | 16 bar | |

| L | 65 mm | |

| weight | 2.800 kg | |

| NPK No. 411 | 278218 | |

| NPK No. 412 | 273221 | |

| BIM-Data | https://www.cadenas.de/de/7100080098 | |

| Availability | ex warehouse | |

| 7100100118 | 100 | |

| ø D | 118 mm | |

| PN | 16 bar | |

| L | 60 mm | |

| weight | 2.900 kg | |

| NPK No. 411 | 278219 | |

| NPK No. 412 | 273222 | |

| BIM-Data | https://www.cadenas.de/de/7100100118 | |

| Availability | ex warehouse | |

| 7100125144 | 125 | |

| ø D | 144 mm | |

| PN | 16 bar | |

| L | 65 mm | |

| weight | 4.300 kg | |

| NPK No. 411 | 278221 | |

| NPK No. 412 | 273223 | |

| BIM-Data | https://www.cadenas.de/de/7100125144 | |

| Availability | ex warehouse | |

| 7100150170 | 150 | |

| ø D | 170 mm | |

| PN | 16 bar | |

| L | 65 mm | |

| weight | 5.100 kg | |

| NPK No. 411 | 278222 | |

| NPK No. 412 | 273224 | |

| BIM-Data | https://www.cadenas.de/de/7100150170 | |

| Availability | ex warehouse | |

| 7100200222 | 200 | |

| ø D | 222 mm | |

| PN | 10 bar | |

| L | 70 mm | |

| weight | 7.300 kg | |

| NPK No. 411 | 278223 | |

| NPK No. 412 | 273235 | |

| BIM-Data | https://www.cadenas.de/de/7100200222 | |

| Availability | ex warehouse | |

| 7100251274 | 250 | |

| ø D | 274 mm | |

| PN | 16 bar | |

| L | 80 mm | |

| weight | 10.900 kg | |

| NPK No. 411 | 278224 | |

| NPK No. 412 | 273246 | |

| BIM-Data | https://www.cadenas.de/de/7100251274 | |

| Availability | ex warehouse | |

| 7100300326 | 300 | |

| ø D | 326 mm | |

| PN | 10 bar | |

| L | 80 mm | |

| weight | 13.800 kg | |

| NPK No. 411 | 278225 | |

| NPK No. 412 | 273237 | |

| BIM-Data | https://www.cadenas.de/de/7100300326 | |

| Availability | ex warehouse | |

| 7100301326 | 300 | |

| ø D | 326 mm | |

| PN | 16 bar | |

| L | 80 mm | |

| weight | 13.800 kg | |

| NPK No. 411 | 278225 | |

| NPK No. 412 | 273247 | |

| BIM-Data | https://www.cadenas.de/de/7100301326 | |

| Availability | ex warehouse | |

| 7100400429 | 400 | |

| ø D | 429 mm | |

| PN | 10 bar | |

| L | 105 mm | |

| weight | 22.500 kg | |

| NPK No. 411 | 278227 | |

| NPK No. 412 | 273238 | |

| BIM-Data | ||

| Availability | on demand | |

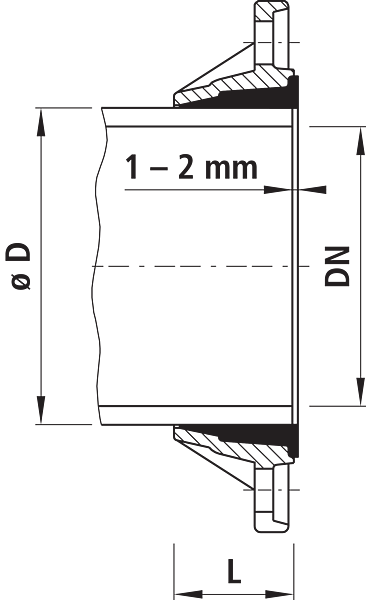

- L = Mounted length

Application

- Die Zweikammerflansch-Technik löst Verbindungs- und Übergangsprobleme aller Art. Sie ist für alle Bereiche des Rohrleitungsbaus einsetzbar. Bei Abweichungen von Normnennweiten sind auf Anfrage auch Sonderanfertigungen möglich.

Characteristics

- Quick and easy installation

- Secure sealing

- Removable at any time

- Flange connection compound

- according to DIN EN 1092-2

- DN 25 to DN 150: PN 10 / 16

- DN 200 to DN 600: PN 10 or 16, specify when ordering - Operating temperature

- max. 40 °C

Installation and assembly

- Cut the pipe ends off at a right angle, do not bevel

- Slide the flange on the smooth pipe end. Fit the rubber end so that it projects 1 to 2mm at the pipe end. Slide the flange up against the counterflange and screw securely in a crosswise direction. Repeat the tightening procedure as often as necessary until all the screws are securely tightened and the connection is sealed.

Material

- Spheroidal Cast Iron EN-GJS-400 (GGG 40)

- EWS coating according to GSK, RAL-GZ 662, layer thickness min. 250 μm

Caution

- For cast pipes to EN 545

- Do not use any additional flange seals.

- Pipe tolerance acc. (see Chapter i)

- Larger nominal widths on request

- Note the screw lengths

- Not trensile strength!

more