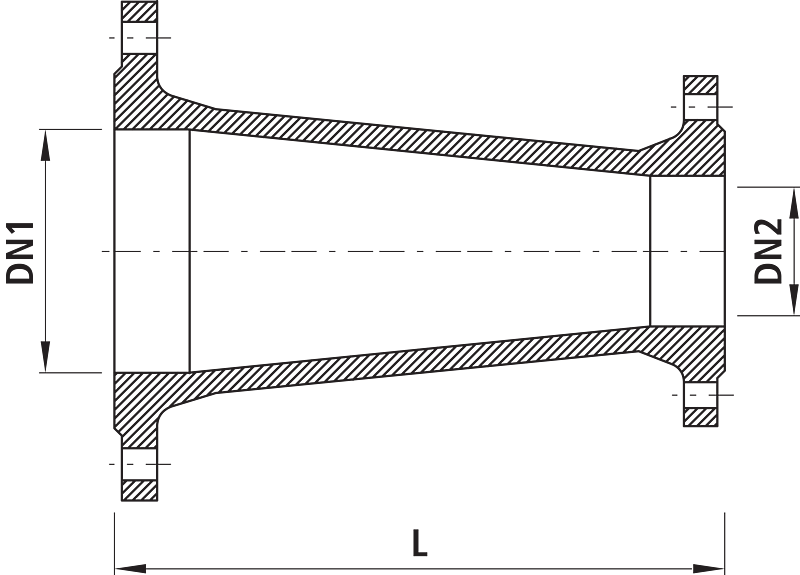

| Article No. | DN1 (mm) | DN2 (mm) | PN (bar) | L (mm) | weight (kg) | Availability | watchlist |

|---|---|---|---|---|---|---|---|

| 8555065050 | 65 | 50 | 5 | 200 | 9.000 | assembly time | |

| 8555080050 | 80 | 50 | 5 | 200 | 7.400 | assembly time | |

| 8555080065 | 80 | 65 | 5 | 200 | 8.200 | assembly time | |

| 8555100050 | 100 | 50 | 5 | 200 | 8.100 | assembly time | |

| 8555100065 | 100 | 65 | 5 | 200 | 8.800 | assembly time | |

| 8555100080 | 100 | 80 | 5 | 200 | 9.500 | assembly time | |

| 8555125065 | 125 | 65 | 5 | 300 | 12.700 | assembly time | |

| 8555125080 | 125 | 80 | 5 | 200 | 10.700 | assembly time | |

| 8555125100 | 125 | 100 | 5 | 200 | 11.400 | assembly time | |

| 8555150080 | 150 | 80 | 5 | 200 | 12.200 | assembly time | |

| 8555150100 | 150 | 100 | 5 | 200 | 12.800 | assembly time | |

| 8555150125 | 150 | 125 | 5 | 200 | 14.100 | assembly time | |

| 8555200100 | 200 | 100 | 5 | 300 | 18.600 | assembly time | |

| 8555200125 | 200 | 125 | 5 | 300 | 20.000 | assembly time | |

| 8555200150 | 200 | 150 | 5 | 300 | 22.000 | assembly time | |

| 8555250200 | 250 | 200 | 5 | 300 | 30.500 | assembly time | |

| 8555300200 | 300 | 200 | 5 | 300 | 35.500 | assembly time | |

| 8555300250 | 300 | 250 | 5 | 300 | 41.000 | assembly time |

DN

watchlist

| 8555065050 | ||

| DN1 | 65 mm | |

| DN2 | 50 mm | |

| PN | 5 bar | |

| L | 200 mm | |

| weight | 9.000 kg | |

| Availability | assembly time | |

| 8555080050 | ||

| DN1 | 80 mm | |

| DN2 | 50 mm | |

| PN | 5 bar | |

| L | 200 mm | |

| weight | 7.400 kg | |

| Availability | assembly time | |

| 8555080065 | ||

| DN1 | 80 mm | |

| DN2 | 65 mm | |

| PN | 5 bar | |

| L | 200 mm | |

| weight | 8.200 kg | |

| Availability | assembly time | |

| 8555100050 | ||

| DN1 | 100 mm | |

| DN2 | 50 mm | |

| PN | 5 bar | |

| L | 200 mm | |

| weight | 8.100 kg | |

| Availability | assembly time | |

| 8555100065 | ||

| DN1 | 100 mm | |

| DN2 | 65 mm | |

| PN | 5 bar | |

| L | 200 mm | |

| weight | 8.800 kg | |

| Availability | assembly time | |

| 8555100080 | ||

| DN1 | 100 mm | |

| DN2 | 80 mm | |

| PN | 5 bar | |

| L | 200 mm | |

| weight | 9.500 kg | |

| Availability | assembly time | |

| 8555125065 | ||

| DN1 | 125 mm | |

| DN2 | 65 mm | |

| PN | 5 bar | |

| L | 300 mm | |

| weight | 12.700 kg | |

| Availability | assembly time | |

| 8555125080 | ||

| DN1 | 125 mm | |

| DN2 | 80 mm | |

| PN | 5 bar | |

| L | 200 mm | |

| weight | 10.700 kg | |

| Availability | assembly time | |

| 8555125100 | ||

| DN1 | 125 mm | |

| DN2 | 100 mm | |

| PN | 5 bar | |

| L | 200 mm | |

| weight | 11.400 kg | |

| Availability | assembly time | |

| 8555150080 | ||

| DN1 | 150 mm | |

| DN2 | 80 mm | |

| PN | 5 bar | |

| L | 200 mm | |

| weight | 12.200 kg | |

| Availability | assembly time | |

| 8555150100 | ||

| DN1 | 150 mm | |

| DN2 | 100 mm | |

| PN | 5 bar | |

| L | 200 mm | |

| weight | 12.800 kg | |

| Availability | assembly time | |

| 8555150125 | ||

| DN1 | 150 mm | |

| DN2 | 125 mm | |

| PN | 5 bar | |

| L | 200 mm | |

| weight | 14.100 kg | |

| Availability | assembly time | |

| 8555200100 | ||

| DN1 | 200 mm | |

| DN2 | 100 mm | |

| PN | 5 bar | |

| L | 300 mm | |

| weight | 18.600 kg | |

| Availability | assembly time | |

| 8555200125 | ||

| DN1 | 200 mm | |

| DN2 | 125 mm | |

| PN | 5 bar | |

| L | 300 mm | |

| weight | 20.000 kg | |

| Availability | assembly time | |

| 8555200150 | ||

| DN1 | 200 mm | |

| DN2 | 150 mm | |

| PN | 5 bar | |

| L | 300 mm | |

| weight | 22.000 kg | |

| Availability | assembly time | |

| 8555250200 | ||

| DN1 | 250 mm | |

| DN2 | 200 mm | |

| PN | 5 bar | |

| L | 300 mm | |

| weight | 30.500 kg | |

| Availability | assembly time | |

| 8555300200 | ||

| DN1 | 300 mm | |

| DN2 | 200 mm | |

| PN | 5 bar | |

| L | 300 mm | |

| weight | 35.500 kg | |

| Availability | assembly time | |

| 8555300250 | ||

| DN1 | 300 mm | |

| DN2 | 250 mm | |

| PN | 5 bar | |

| L | 300 mm | |

| weight | 41.000 kg | |

| Availability | assembly time | |

Caution

- Special lengths up to 2000 mm as well as special shapes according to sketches are available on request in powder/coated steel 37

Application

- Die Hawle Flansch-Armaturen sind für den Einsatz in Schieberschächten sowie Industrieanlagen konzipiert. Bei engen Platzverhältnissen bietet Hawle eine Reihe exklusiver Problemlösungen an: z.B. Reduzier-Schieber, Combi-T etc. Nebst Norm-Formstücken fertigt Hawle auch individuelle Formteile nach Ihren Wünschen an. (Siehe Katalog Anlagenbau, Kapitel D)

- The employment of natural gas has to be specified, so that the required tests (PG1 for Underground Fittings an d PG3 Fittings in Installations) with the associated test certificate 3.1B can made according to DIN EN 10204.

- Flanschen bemessen nach EN1092-2

- Druckstufen

- Standard DN 25 bis DN 150 Flanschen PN 16

- DN 200 bis DN 600 Flanschen PN 10

- DN 200 bis DN 600 Flanschen PN 16

bei Bestellung angeben

Characteristics

- Pressure class PN 5

Material

- Gehäuse

- EN-GJS-400 (GGG 40)

- EWS-Beschichtung nach GSK, RAL-GZ 662, Schichtdicke min. 250 μm

- Lackierung: Gelb RAL 1021

more