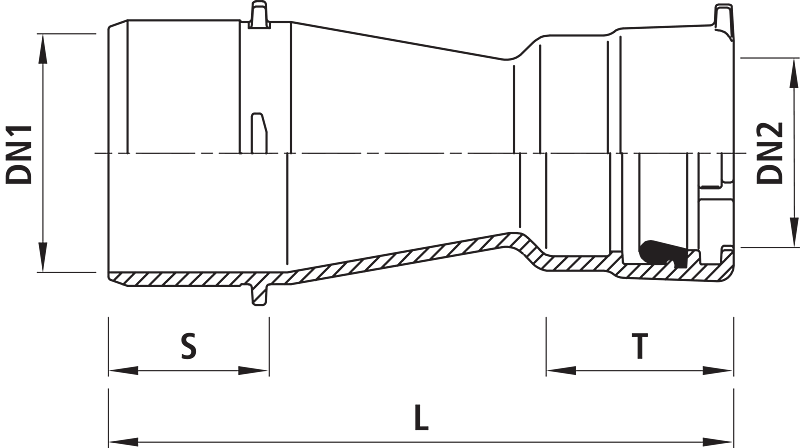

| Article No. | DN1 (mm) | DN2 (mm) | PN (bar) | L (mm) | S | T (mm) | weight (kg) | Availability | watchlist |

|---|---|---|---|---|---|---|---|---|---|

| 5365100080 | 100 | 80 | 5 | 310 | 95 | 105 | 7.000 | assembly time | |

| 5365125080 | 125 | 80 | 5 | 370 | 100 | 105 | 9.400 | assembly time | |

| 5365125100 | 125 | 100 | 5 | 340 | 100 | 120 | 9.800 | assembly time | |

| 5365150080 | 150 | 80 | 5 | 420 | 100 | 105 | 10.800 | assembly time | |

| 5365150100 | 150 | 100 | 5 | 395 | 100 | 120 | 11.800 | assembly time | |

| 5365150125 | 150 | 125 | 5 | 335 | 100 | 125 | 12.400 | assembly time | |

| 5365200100 | 200 | 100 | 5 | 500 | 105 | 120 | 17.500 | assembly time | |

| 5365200125 | 200 | 125 | 5 | 435 | 105 | 125 | 18.200 | assembly time | |

| 5365200150 | 200 | 150 | 5 | 410 | 105 | 125 | 17.200 | assembly time | |

| 5365250150 | 250 | 150 | 5 | 430 | 105 | 125 | 30.000 | assembly time | |

| 5365250200 | 250 | 200 | 5 | 475 | 150 | 145 | 30.300 | assembly time | |

| 5365300100 | 300 | 100 | 5 | 450 | 105 | 120 | 42.000 | assembly time | |

| 5365300150 | 300 | 150 | 5 | 480 | 105 | 125 | 47.000 | assembly time | |

| 5365300200 | 300 | 200 | 5 | 625 | 165 | 145 | 50.200 | assembly time | |

| 5365300250 | 300 | 250 | 5 | 525 | 165 | 145 | 53.000 | assembly time |

DN

watchlist

| 5365100080 | ||

| DN1 | 100 mm | |

| DN2 | 80 mm | |

| PN | 5 bar | |

| L | 310 mm | |

| S | 95 | |

| T | 105 mm | |

| weight | 7.000 kg | |

| Availability | assembly time | |

| 5365125080 | ||

| DN1 | 125 mm | |

| DN2 | 80 mm | |

| PN | 5 bar | |

| L | 370 mm | |

| S | 100 | |

| T | 105 mm | |

| weight | 9.400 kg | |

| Availability | assembly time | |

| 5365125100 | ||

| DN1 | 125 mm | |

| DN2 | 100 mm | |

| PN | 5 bar | |

| L | 340 mm | |

| S | 100 | |

| T | 120 mm | |

| weight | 9.800 kg | |

| Availability | assembly time | |

| 5365150080 | ||

| DN1 | 150 mm | |

| DN2 | 80 mm | |

| PN | 5 bar | |

| L | 420 mm | |

| S | 100 | |

| T | 105 mm | |

| weight | 10.800 kg | |

| Availability | assembly time | |

| 5365150100 | ||

| DN1 | 150 mm | |

| DN2 | 100 mm | |

| PN | 5 bar | |

| L | 395 mm | |

| S | 100 | |

| T | 120 mm | |

| weight | 11.800 kg | |

| Availability | assembly time | |

| 5365150125 | ||

| DN1 | 150 mm | |

| DN2 | 125 mm | |

| PN | 5 bar | |

| L | 335 mm | |

| S | 100 | |

| T | 125 mm | |

| weight | 12.400 kg | |

| Availability | assembly time | |

| 5365200100 | ||

| DN1 | 200 mm | |

| DN2 | 100 mm | |

| PN | 5 bar | |

| L | 500 mm | |

| S | 105 | |

| T | 120 mm | |

| weight | 17.500 kg | |

| Availability | assembly time | |

| 5365200125 | ||

| DN1 | 200 mm | |

| DN2 | 125 mm | |

| PN | 5 bar | |

| L | 435 mm | |

| S | 105 | |

| T | 125 mm | |

| weight | 18.200 kg | |

| Availability | assembly time | |

| 5365200150 | ||

| DN1 | 200 mm | |

| DN2 | 150 mm | |

| PN | 5 bar | |

| L | 410 mm | |

| S | 105 | |

| T | 125 mm | |

| weight | 17.200 kg | |

| Availability | assembly time | |

| 5365250150 | ||

| DN1 | 250 mm | |

| DN2 | 150 mm | |

| PN | 5 bar | |

| L | 430 mm | |

| S | 105 | |

| T | 125 mm | |

| weight | 30.000 kg | |

| Availability | assembly time | |

| 5365250200 | ||

| DN1 | 250 mm | |

| DN2 | 200 mm | |

| PN | 5 bar | |

| L | 475 mm | |

| S | 150 | |

| T | 145 mm | |

| weight | 30.300 kg | |

| Availability | assembly time | |

| 5365300100 | ||

| DN1 | 300 mm | |

| DN2 | 100 mm | |

| PN | 5 bar | |

| L | 450 mm | |

| S | 105 | |

| T | 120 mm | |

| weight | 42.000 kg | |

| Availability | assembly time | |

| 5365300150 | ||

| DN1 | 300 mm | |

| DN2 | 150 mm | |

| PN | 5 bar | |

| L | 480 mm | |

| S | 105 | |

| T | 125 mm | |

| weight | 47.000 kg | |

| Availability | assembly time | |

| 5365300200 | ||

| DN1 | 300 mm | |

| DN2 | 200 mm | |

| PN | 5 bar | |

| L | 625 mm | |

| S | 165 | |

| T | 145 mm | |

| weight | 50.200 kg | |

| Availability | assembly time | |

| 5365300250 | ||

| DN1 | 300 mm | |

| DN2 | 250 mm | |

| PN | 5 bar | |

| L | 525 mm | |

| S | 165 | |

| T | 145 mm | |

| weight | 53.000 kg | |

| Availability | assembly time | |

Application

- All BAIO® spigot–end fittings and shaped parts can be inserted shear–protected in the BAIO® sleeves.

- BAIO® ist ein Baukasten-System. Sämtliche Spitzend-Armaturen und Formstücke lassen sich schubsicher in die BAIO®-Muffen stecken. Somit lassen sich selbst anspruchsvollste SchieberKombinationen, bis DN 300, flanschlos montieren. Zudem ist die Verbindung ohne Werkzeug demontierbar. Sämtliche BAIO®-Armaturen und -Formstücke sind serienmässig mit TYTON-Dichtungen für Gas ausgerüstet. Die Steckmuffe ist für folgende Rohrarten geeignet:

- Gussrohre

- Mit Standard-TYTON-Dichtung (Nr. 5395), Schubsicherung mit TYTON-SIT-Dichtung (Nr. 5397) oder BAIO®-SIT (Nr. 5380); aussenliegend demontierbar - Ecopur-Gussrohre

- Mit Standard-TYTON-Dichtung (Nr. 5395), Schubsicherung mit BAIO®-SIT (Nr. 5380); aussenliegend demontierbar - PE-Rohre

- Mit PE-Anschweissende (Nr. 4520) - Stahl-Rohr

- Mit Stahl-Übergang 4531 - The use with natural gas must be specified in order for the required testing according to DIN 3230-5 (PG1 for underground valves and PG3 for valves in installations) to be performed, along with the corresponding certificate of acceptance 3.1 according to DIN EN 10204.

Characteristics

- Abwinkelung

- DN 80 bis DN 150: max. 3°

- DN 200 bis DN 300: max. 2° - Pressure class PN 5

Thrust protection

- BAIO®-SIT shearing protection (No. 5380)

Adapters

- Equipped as standard with a seal for cast pipes (No. 5395)

- PE weld-on end (No. 4520)

Material

Housing

-Spheroidal graphite cast iron EN-GJS-400 (GGG 40)

- EWS coating according to GSK, RAL-GZ 662, minimum coating thickness 250 μm

-Coating: Yellow RAL 1021- Push-in sockets

- according to DIN 28603 - Dichtungen

- NBR

more