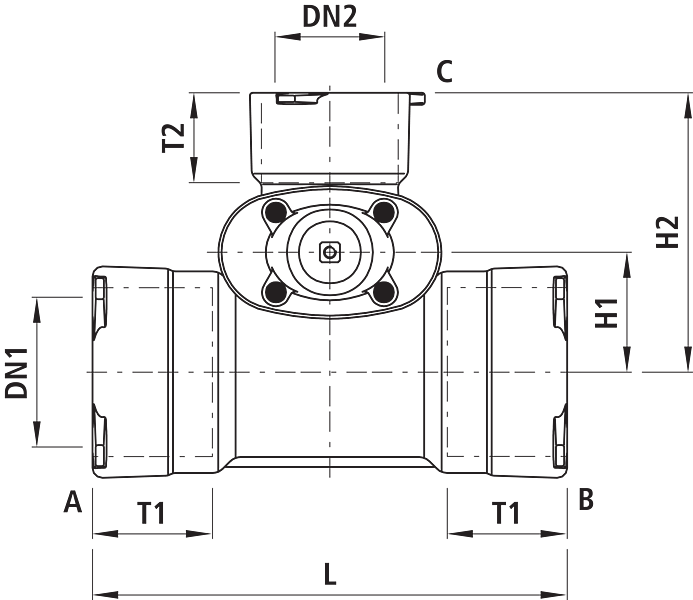

| Article No. | DN1 (mm) | DN2 (mm) | PN (bar) | L (mm) | H (mm) | H1 (mm) | H2 (mm) | T1 (mm) | T2 (mm) | weight (kg) | Availability | watchlist |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4375080080 | 80 | 80 | 5 | 410 | 313 | 78 | 220 | 105 | 105 | 26.300 | assembly time | |

| 4375100080 | 100 | 80 | 5 | 435 | 313 | 88 | 230 | 120 | 105 | 29.500 | assembly time | |

| 4375100100 | 100 | 100 | 5 | 455 | 343 | 90 | 255 | 120 | 120 | 35.000 | assembly time | |

| 4375125080 | 125 | 80 | 5 | 430 | 313 | 105 | 240 | 125 | 105 | 32.000 | assembly time | |

| 4375125100 | 125 | 100 | 5 | 435 | 343 | 105 | 270 | 125 | 120 | 38.500 | assembly time | |

| 4375125125 | 125 | 125 | 5 | 440 | 421 | 115 | 290 | 125 | 125 | 54.000 | assembly time | |

| 4375150080 | 150 | 80 | 5 | 450 | 313 | 116 | 260 | 125 | 105 | 35.000 | assembly time | |

| 4375150100 | 150 | 100 | 5 | 475 | 343 | 115 | 280 | 125 | 120 | 42.000 | assembly time | |

| 4375150125 | 150 | 125 | 5 | 565 | 421 | 120 | 295 | 125 | 125 | 59.500 | assembly time | |

| 4375150150 | 150 | 150 | 5 | 565 | 433 | 120 | 300 | 125 | 125 | 61.000 | assembly time | |

| 4375200080 | 200 | 80 | 5 | 490 | 313 | 138 | 280 | 145 | 105 | 46.000 | assembly time | |

| 4375200100 | 200 | 100 | 5 | 515 | 343 | 140 | 305 | 145 | 120 | 51.500 | assembly time | |

| 4375200125 | 200 | 125 | 5 | 605 | 421 | 147 | 320 | 145 | 125 | 71.000 | assembly time | |

| 4375200150 | 200 | 150 | 5 | 605 | 433 | 147 | 325 | 145 | 125 | 73.000 | assembly time | |

| 4375200200 | 200 | 200 | 5 | 670 | 541 | 150 | 355 | 145 | 145 | 100.000 | assembly time |

DN

watchlist

| 4375080080 | ||

| DN1 | 80 mm | |

| DN2 | 80 mm | |

| PN | 5 bar | |

| L | 410 mm | |

| H | 313 mm | |

| H1 | 78 mm | |

| H2 | 220 mm | |

| T1 | 105 mm | |

| T2 | 105 mm | |

| weight | 26.300 kg | |

| Availability | assembly time | |

| 4375100080 | ||

| DN1 | 100 mm | |

| DN2 | 80 mm | |

| PN | 5 bar | |

| L | 435 mm | |

| H | 313 mm | |

| H1 | 88 mm | |

| H2 | 230 mm | |

| T1 | 120 mm | |

| T2 | 105 mm | |

| weight | 29.500 kg | |

| Availability | assembly time | |

| 4375100100 | ||

| DN1 | 100 mm | |

| DN2 | 100 mm | |

| PN | 5 bar | |

| L | 455 mm | |

| H | 343 mm | |

| H1 | 90 mm | |

| H2 | 255 mm | |

| T1 | 120 mm | |

| T2 | 120 mm | |

| weight | 35.000 kg | |

| Availability | assembly time | |

| 4375125080 | ||

| DN1 | 125 mm | |

| DN2 | 80 mm | |

| PN | 5 bar | |

| L | 430 mm | |

| H | 313 mm | |

| H1 | 105 mm | |

| H2 | 240 mm | |

| T1 | 125 mm | |

| T2 | 105 mm | |

| weight | 32.000 kg | |

| Availability | assembly time | |

| 4375125100 | ||

| DN1 | 125 mm | |

| DN2 | 100 mm | |

| PN | 5 bar | |

| L | 435 mm | |

| H | 343 mm | |

| H1 | 105 mm | |

| H2 | 270 mm | |

| T1 | 125 mm | |

| T2 | 120 mm | |

| weight | 38.500 kg | |

| Availability | assembly time | |

| 4375125125 | ||

| DN1 | 125 mm | |

| DN2 | 125 mm | |

| PN | 5 bar | |

| L | 440 mm | |

| H | 421 mm | |

| H1 | 115 mm | |

| H2 | 290 mm | |

| T1 | 125 mm | |

| T2 | 125 mm | |

| weight | 54.000 kg | |

| Availability | assembly time | |

| 4375150080 | ||

| DN1 | 150 mm | |

| DN2 | 80 mm | |

| PN | 5 bar | |

| L | 450 mm | |

| H | 313 mm | |

| H1 | 116 mm | |

| H2 | 260 mm | |

| T1 | 125 mm | |

| T2 | 105 mm | |

| weight | 35.000 kg | |

| Availability | assembly time | |

| 4375150100 | ||

| DN1 | 150 mm | |

| DN2 | 100 mm | |

| PN | 5 bar | |

| L | 475 mm | |

| H | 343 mm | |

| H1 | 115 mm | |

| H2 | 280 mm | |

| T1 | 125 mm | |

| T2 | 120 mm | |

| weight | 42.000 kg | |

| Availability | assembly time | |

| 4375150125 | ||

| DN1 | 150 mm | |

| DN2 | 125 mm | |

| PN | 5 bar | |

| L | 565 mm | |

| H | 421 mm | |

| H1 | 120 mm | |

| H2 | 295 mm | |

| T1 | 125 mm | |

| T2 | 125 mm | |

| weight | 59.500 kg | |

| Availability | assembly time | |

| 4375150150 | ||

| DN1 | 150 mm | |

| DN2 | 150 mm | |

| PN | 5 bar | |

| L | 565 mm | |

| H | 433 mm | |

| H1 | 120 mm | |

| H2 | 300 mm | |

| T1 | 125 mm | |

| T2 | 125 mm | |

| weight | 61.000 kg | |

| Availability | assembly time | |

| 4375200080 | ||

| DN1 | 200 mm | |

| DN2 | 80 mm | |

| PN | 5 bar | |

| L | 490 mm | |

| H | 313 mm | |

| H1 | 138 mm | |

| H2 | 280 mm | |

| T1 | 145 mm | |

| T2 | 105 mm | |

| weight | 46.000 kg | |

| Availability | assembly time | |

| 4375200100 | ||

| DN1 | 200 mm | |

| DN2 | 100 mm | |

| PN | 5 bar | |

| L | 515 mm | |

| H | 343 mm | |

| H1 | 140 mm | |

| H2 | 305 mm | |

| T1 | 145 mm | |

| T2 | 120 mm | |

| weight | 51.500 kg | |

| Availability | assembly time | |

| 4375200125 | ||

| DN1 | 200 mm | |

| DN2 | 125 mm | |

| PN | 5 bar | |

| L | 605 mm | |

| H | 421 mm | |

| H1 | 147 mm | |

| H2 | 320 mm | |

| T1 | 145 mm | |

| T2 | 125 mm | |

| weight | 71.000 kg | |

| Availability | assembly time | |

| 4375200150 | ||

| DN1 | 200 mm | |

| DN2 | 150 mm | |

| PN | 5 bar | |

| L | 605 mm | |

| H | 433 mm | |

| H1 | 147 mm | |

| H2 | 325 mm | |

| T1 | 145 mm | |

| T2 | 125 mm | |

| weight | 73.000 kg | |

| Availability | assembly time | |

| 4375200200 | ||

| DN1 | 200 mm | |

| DN2 | 200 mm | |

| PN | 5 bar | |

| L | 670 mm | |

| H | 541 mm | |

| H1 | 150 mm | |

| H2 | 355 mm | |

| T1 | 145 mm | |

| T2 | 145 mm | |

| weight | 100.000 kg | |

| Availability | assembly time | |

- Height H: Pipe axis up to the spindle end

Application

- BAIO® ist ein Baukasten-System. Sämtliche Spitzend-Armaturen und Formstücke lassen sich schubsicher in die BAIO®-Muffen stecken. Somit lassen sich selbst anspruchsvollste SchieberKombinationen, bis DN 300, flanschlos montieren. Zudem ist die Verbindung ohne Werkzeug demontierbar. Sämtliche BAIO®-Armaturen und -Formstücke sind serienmässig mit TYTON-Dichtungen für Gas ausgerüstet. Die Steckmuffe ist für folgende Rohrarten geeignet:

- Gussrohre

- Mit Standard-TYTON-Dichtung (Nr. 5395), Schubsicherung mit TYTON-SIT-Dichtung (Nr. 5397) oder BAIO®-SIT (Nr. 5380); aussenliegend demontierbar - Ecopur-Gussrohre

- Mit Standard-TYTON-Dichtung (Nr. 5395), Schubsicherung mit BAIO®-SIT (Nr. 5380); aussenliegend demontierbar - PE-Rohre

- Mit PE-Anschweissende (Nr. 4520) - Stahl-Rohr

- Mit Stahl-Übergang 4531 - The use with natural gas must be specified in order for the required testing according to DIN 3230-5 (PG1 for underground valves and PG3 for valves in installations) to be performed, along with the corresponding certificate of acceptance 3.1 according to DIN EN 10204.

Characteristics

- Abwinkelung

- DN 80 bis DN 150: max. 3°

- DN 200 bis DN 300: max. 2° - Pressure class PN 5

Thrust protection

- BAIO®-SIT shearing protection (No. 5380)

Adapters

- Equipped as standard with a seal for cast pipes (No. 5395)

- PE weld/on end (No. 4520, No. 4526)

Material

Housing

-Spheroidal graphite cast iron EN-GJS-400 (GGG 40)

- EWS coating according to GSK, RAL-GZ 662, minimum coating thickness 250 μm

-Coating: Yellow RAL 1021- Push-in sockets

- according to DIN 28603 - Dichtungen

- NBR

Caution

- Installation loops (No. 5347) should also be employed for installation in existing lines.

more