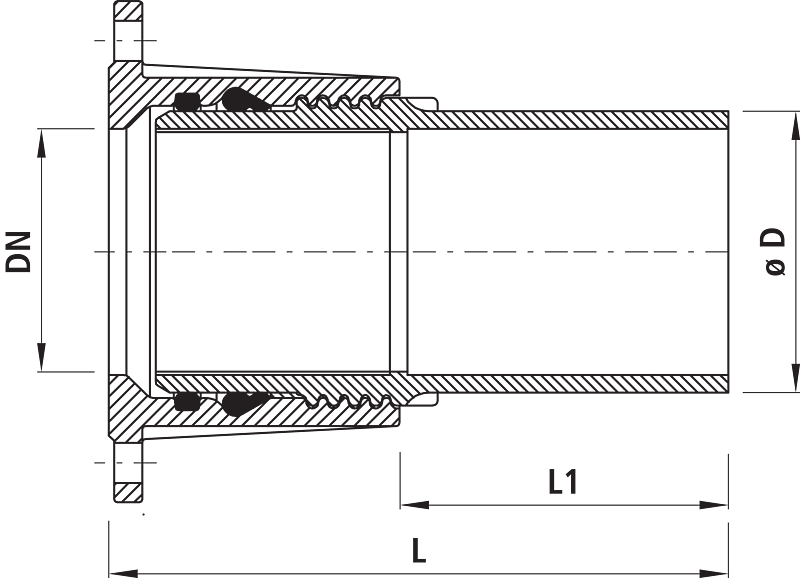

| Article No. | DN | ø D | PN (bar) | L (mm) | L1 (mm) | weight (kg) | Availability | watchlist |

|---|---|---|---|---|---|---|---|---|

| 3105050063 | ||||||||

| 3105080090 | ||||||||

| 3105100110 | ||||||||

| 3105100125 | ||||||||

| 3105150160 | ||||||||

| 3105150180 | ||||||||

| 3105200200 | ||||||||

| 3105200225 |

DN

watchlist

| 3105050063 | ||

| ø D | ||

| PN | ||

| L | ||

| L1 | ||

| weight | ||

| Availability | ||

| 3105080090 | ||

| ø D | ||

| PN | ||

| L | ||

| L1 | ||

| weight | ||

| Availability | ||

| 3105100110 | ||

| ø D | ||

| PN | ||

| L | ||

| L1 | ||

| weight | ||

| Availability | ||

| 3105100125 | ||

| ø D | ||

| PN | ||

| L | ||

| L1 | ||

| weight | ||

| Availability | ||

| 3105150160 | ||

| ø D | ||

| PN | ||

| L | ||

| L1 | ||

| weight | ||

| Availability | ||

| 3105150180 | ||

| ø D | ||

| PN | ||

| L | ||

| L1 | ||

| weight | ||

| Availability | ||

| 3105200200 | ||

| ø D | ||

| PN | ||

| L | ||

| L1 | ||

| weight | ||

| Availability | ||

| 3105200225 | ||

| ø D | ||

| PN | ||

| L | ||

| L1 | ||

| weight | ||

| Availability | ||

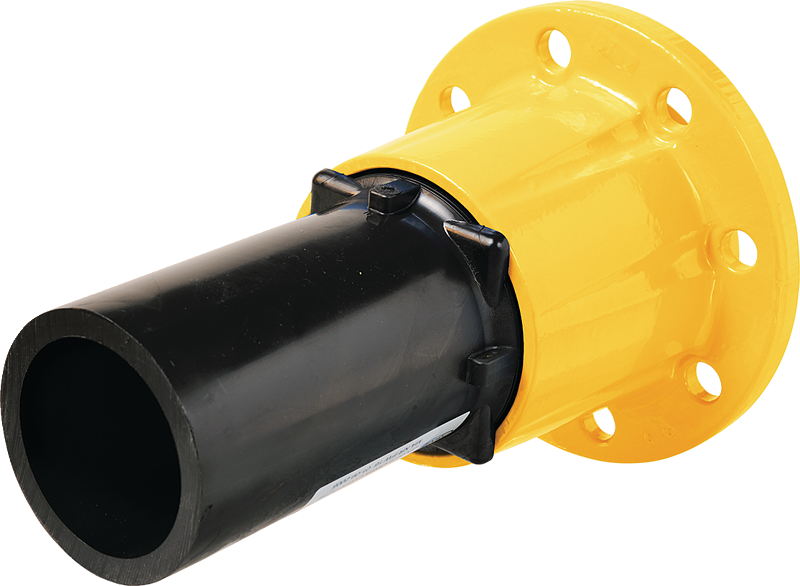

Application

- Die PE-Anschweiss-Armaturen können mit Elektroschweissmuffen, Heizelement-Stumpfschweissungen oder mechanischen Klemmverbindungen kraftschlüssig verbunden werden.

- Die Stutzen sind mit doppelter Abdichtung (Lippendichtung, O-Ring-Dichtung) und Stützhülse kraftschlüssig in den Armaturenkörper eingeschraubt.

- Die PE-Anschweissenden können bei Schiebern einzeln ausgewechselt werden.

- Geeignet für alle PE-Rohre. Die Verarbeitung richtet sich nach den Richtlinien des VKR (Verband der Kunststoff-Rohre und Rohrleitungsteile, Aarau).

- The use with natural gas must be specified in order for the required testing according to DIN 3230-5 (PG1 for underground valves and PG3 for valves in installations) to be performed, along with the corresponding certificate of acceptance 3.1 according to DIN EN 10204.

Characteristics

- The PE stubs can be replaced if needed or during modifications. This allows the valves to be reused in case of a defective PE stub.

- Socket fusion stubs standard: PE 100, SDR 11, available upon request with SDR 17 bore.

- Pressure class PN 5

Flange connection dimension

- DN 200: PN 10

Material

- Housing

- Spheroidal graphite cast iron EN-GJS-400 (GGG 40)

- EWS coating according to GSK, RAL-GZ 662, minimum coating thickness 250 μm

- Coating: Yellow RAL 1021 - Seals

- O-ring: NBR-Duo

- Socket seal: NBR - Einschweissstutzen

- Standard: PE 100, SDR 11

- Auf Anfrage: auf SDR 17 ausgedreht - Stützhülse

- INOX

more